The timber industry plays a crucial role in the transition to more environmentally friendly construction and interior design practices . Among the popular materials used in this industry, wood panels stand out for their low environmental impact and their contribution to reducing greenhouse gas emissions .

In this article, we will explore the environmental benefits of wood panels, their manufacturing processes, responsible logging, challenges and possible improvements , and the importance of making responsible choices . Come go behind the scenes of wood panel production and discover in-depth what is behind this industry , highlighting its environmental benefits .

The environmental benefits of wood panels

And yes, contrary to what one might think, the production and use, if controlled, of wood panels could be beneficial . Wood panels, even once transformed, have many advantages :

A renewable resource and environmental impact

The wood used in the manufacture of the panels generally comes from responsibly managed forests. Foresters replant trees to ensure continued regeneration. Compared to non-renewable materials such as concrete or plastic. The use of wood panels helps conserve natural resources.

Carbon storage :

Trees absorb carbon dioxide (CO2) from the atmosphere as they grow. The wood used to make the panels then stores this carbon. By choosing wood panels, you contribute to carbon sequestration. Thus helping to reduce atmospheric CO2 levels and combat climate change.

Low carbon footprint :

Wood panels have a lower carbon footprint than many other building materials. Wood production requires less energy. And this also allows the reduction of greenhouse gases. Unlike manufacturing materials such as steel or concrete. The use of wood panels in construction can therefore help reduce CO2 emissions associated with buildings.

Reduced gray energy :

Embodied energy refers to the total energy used throughout the life cycle of a material. Including its extraction, manufacturing, transportation and disposal. Wood panels have relatively low embodied energy compared to other building materials. Which implies that they require less energy for their production and use less intensive resources.

Recycling and reuse :

Wood panels can undergo recycling or reuse at the end of their useful life. Waste wood can be used to make particle boards. But also in biomass fuel or other wood-based products. Recycling and reusing wood panels helps reduce the amount of waste sent to landfill. Thus preserving natural resources.

Thermal and acoustic insulation :

Wood panels also offer insulating properties. This reduces energy consumption for heating and cooling buildings. They contribute to better thermal and acoustic insulation. This can improve the energy efficiency of buildings and reduce the carbon footprint associated with the use of other energy sources.

In summary, wood panels have significant environmental benefits , including their renewable nature, their ability to store carbon, their low carbon footprint, their recyclability and their insulating properties. That is to say, their use in construction and interior design can contribute to more sustainable practices and the reduction of greenhouse gas emissions .

Wood panel manufacturing processes

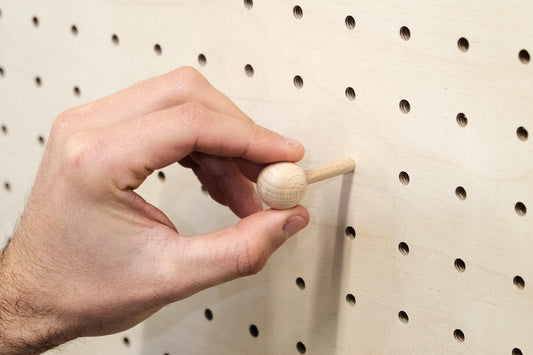

Manufacturers produce wood panels using different processes. Each with distinct characteristics and specific environmental impacts. Some of the most commonly used processes include, for example , plywood , MDF (medium density fiberboard) and OSB (oriented strand board). If you want to deepen your knowledge of these processes. We invite you to consult our blog articles dealing with this subject by clicking here.

Each of these processes involves the use of glues and chemicals, which can pose a sustainability challenge .

However, the industry is actively committed to adopting glues based on natural products that are less harmful to the environment. These advances help reduce the ecological footprint of wood panel manufacturing processes. In addition, particular attention is paid to the recovery and recycling of wood waste generated by these processes. This practice helps minimize environmental impact by reducing the amount of waste sent to landfill and promoting more efficient use of natural resources.

Responsible logging

Responsible logging plays a crucial role in preserving the environment when producing wood panels . By adopting responsible practices, such as preserving biodiversity, protecting ecosystems and reducing excessive exploitation of natural resources, the industry strives to minimize its environmental impact .

To guarantee sustainable forest management, initiatives such as certifications and forest labels have been put in place. The Forest Stewardship Council (FSC) is one of these internationally recognized labels. By obtaining FSC certification, companies commit to meeting rigorous standards for sustainable forest management.

Forest certifications and labels encourage industry players to implement responsible practices throughout the supply chain, from planting to the production of wood panels . They therefore ensure that forests are managed responsibly , taking into account social, economic and environmental aspects.

Challenges and possible improvements

The wood panel industry faces significant environmental impact challenges . Among these challenges, we can first mention the management of waste generated by the production of wood panels. It is crucial to develop effective strategies to minimize waste and promote recycling , in order to reduce the ecological footprint of the industry.

Another major issue is the consumption of water and energy associated with manufacturing processes . The natural resources used in these processes must be used judiciously and efficiently . This is why technological advances are being developed to reduce water and energy consumption in the production of wood panels . New, more efficient methods and equipment are emerging, thus limiting the environmental impact of the industry.

At the same time, it is essential to take measures to reduce atmospheric emissions linked to manufacturing processes. Responsible management of polluting substances used in the production of wood panels is essential. Stricter standards are in place to control and reduce these emissions.

The use of recycled wood panels is a promising approach to reducing the ecological footprint of the wood panel industry. By recycling existing panels , it is possible to minimize the demand for new raw materials and conserve natural resources . Alternative materials based on plant fibers offer an environmentally friendly solution for the production of wood panels. Thus helping to reduce the overall environmental impact.

The importance of responsible choice to reduce environmental impact

Wood panels have many environmental benefits over other building materials. First of all, wood is a renewable resource. Which means that the trees used to manufacture the panels can be replanted to ensure sustainable forest management . Additionally, wood is a material with a low carbon footprint , as it stores carbon while it grows and maintains it even after being transformed into panels . Thus, the use of wood panels contributes to carbon sequestration and the reduction of greenhouse gas emissions , thus participating in the fight against climate change.

Conclusion

Wood panels offer many environmental benefits , and their use helps promote a sustainable future for all. Their renewable nature is one of the most important assets .

Additionally, wood panels have a relatively small carbon footprint compared to other building materials . Because wood is a natural material that absorbs and stores carbon dioxide during its growth .

The wood industry is aware of environmental issues and is actively engaged in the implementation of sustainable practices . Promoting responsible forestry is one of the main priorities . Alongside responsible forestry, the industry is also looking for solutions to reduce the environmental impacts of manufacturing processes.

By supporting a wood industry committed to sustainable practices. We help promote a sustainable future for all , where environmental protection is a priority. Making responsible choices when using wood panels is a tangible way to support this vision. And this allows us to make a positive difference for our planet .